Our modern sawing equipment guarantees precise sawing segments with the closest tolerances.

We offer solutions in different lot sizes in the dimension range up to Ø 720 mm.

On request we saw larger dimension ranges.

We guarantee all-round service from a single-source and offer the following preprocessing possibilities in this regard:

| Planing |

| Centring |

| Drilling/deep-hole drilling |

| Chamfering |

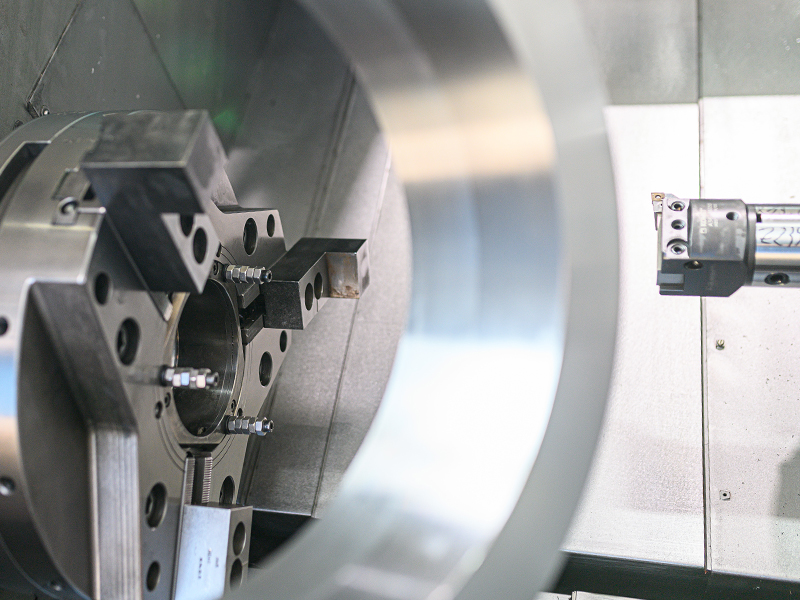

| Turning |

| Milling |

| Polishing |

Additional preprocessing possibilities on request.

Cleaning and degreasing of parts

| With emulsion |

| With ultrasonic cleaning systems |

We drill perfect centres for your specific needs. We offer solutions in various diameters and up to a length of 2,000 mm. From diameter 2.5 mm to diameter 8.0 mm in accordance with DIN 332.

We can advise you on questions concerning customs and import regulations, as well as transport insurance issues. With our own efficient fleet, we guarantee an on-schedule, high-quality delivery. We offer a broad spectrum of transport and logistics solutions.

Challenge us.

Our services in the “heat-treatment area”:

| Tempering (+QT) |

| Normalizing (+N) |

| Annealing (+A) / (+FP) |

Additional processing methods can be implemented in accordance with your specifications.

ASS Stahlservice GmbH offers services in the area of “quality tests”. An overview of our services:

Destructive material testing:

| Notch bar impact test |

| Hardness test / hardness curve |

| Metallography (purity and structure determination) |

| End quenching test |

| (Other tests on request) |

Non-destructive testing:

| Ultrasonic testing |

| Magnetic particle testing |

| Dye-penetrant testing |

| Spectral analysis / test for mixed-up materials |

| Hardness testing |

| (Other tests on request) |

Other services:

| Material acceptance by DNV, ABS, GL, LRS, TÜV, BV |

| Restamping (TÜV) |

| (Other tests on request) |